BUCKRIDGE FLINTLOCKS

|

This lock is over 2 centuries old. Originally hand cut, each part is designed to fit ONLY with the pieces in this lock. Each feature of each part, was created relative to the mating parts. In other words, if something wears out, breaks or is lost, there are no replacement parts.

My job is to parametrically duplicate this priceless assembly so it can be reproduced by the family owned Buck Ridge Flintlock Company. Please check them out at https://www.buckridgeflintlocks.com/ and tell them I sent you. |

The Original Parts

Models

Stainless Steel, 3D Printed Parts

Individual Parts

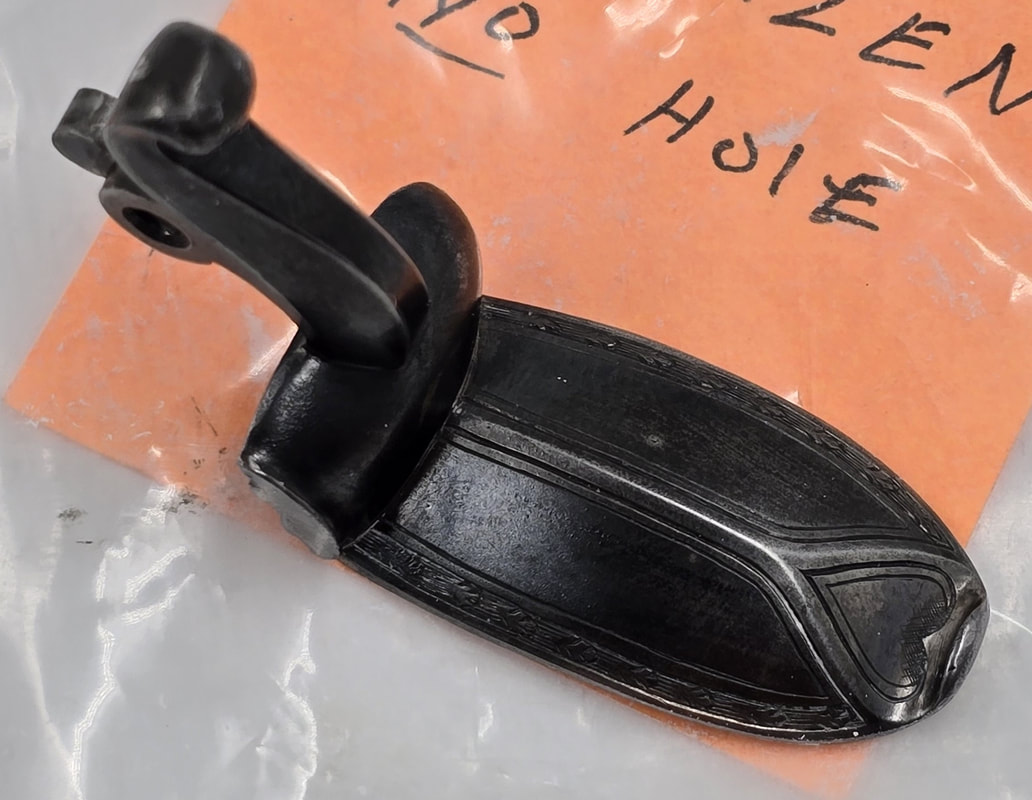

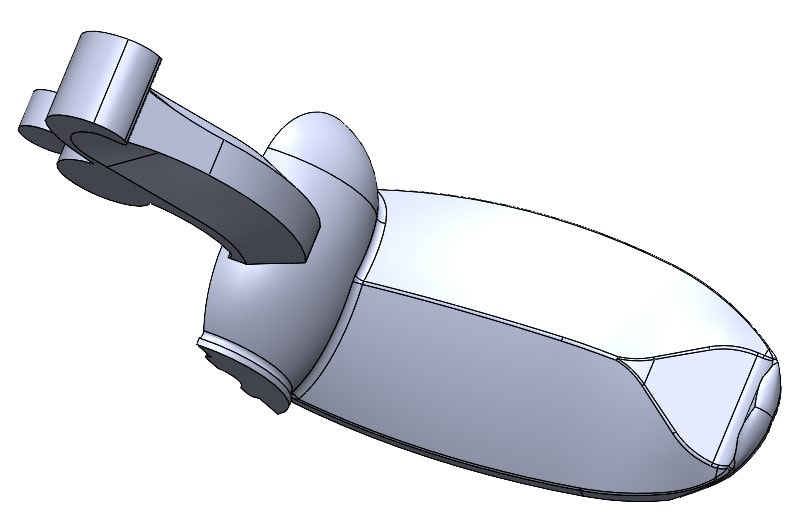

HammerIt may look easy, but don't let the finished product fool you, the hammer was by far the most difficult part to reproduce. It is not symmetric and each organic feature changes relative to it's rotation on the Lock Plate.

Original Part

Model

Metal 3D Printed Part

|

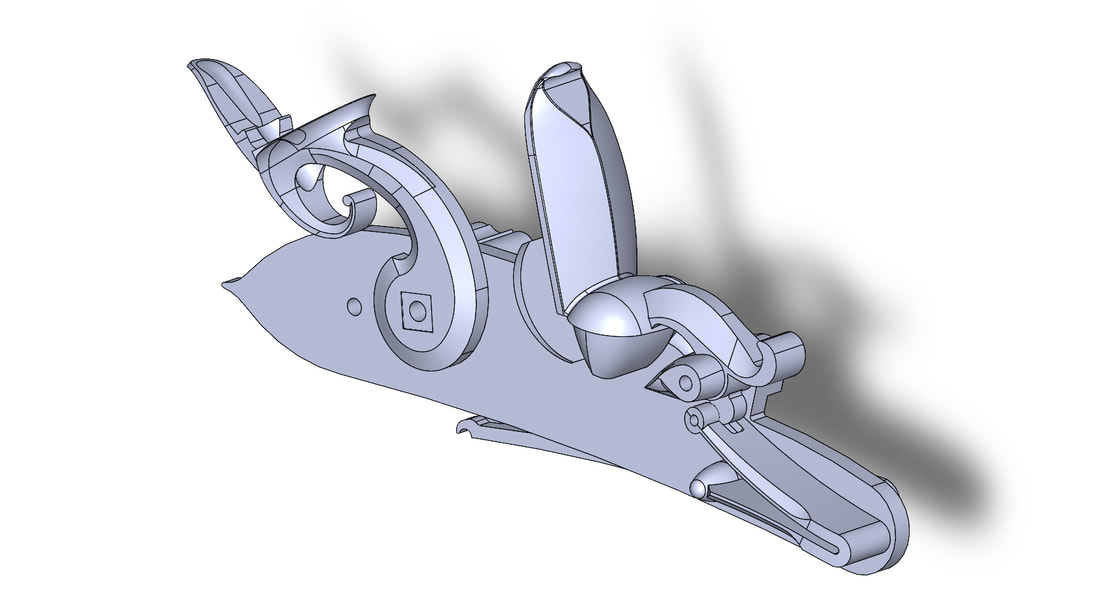

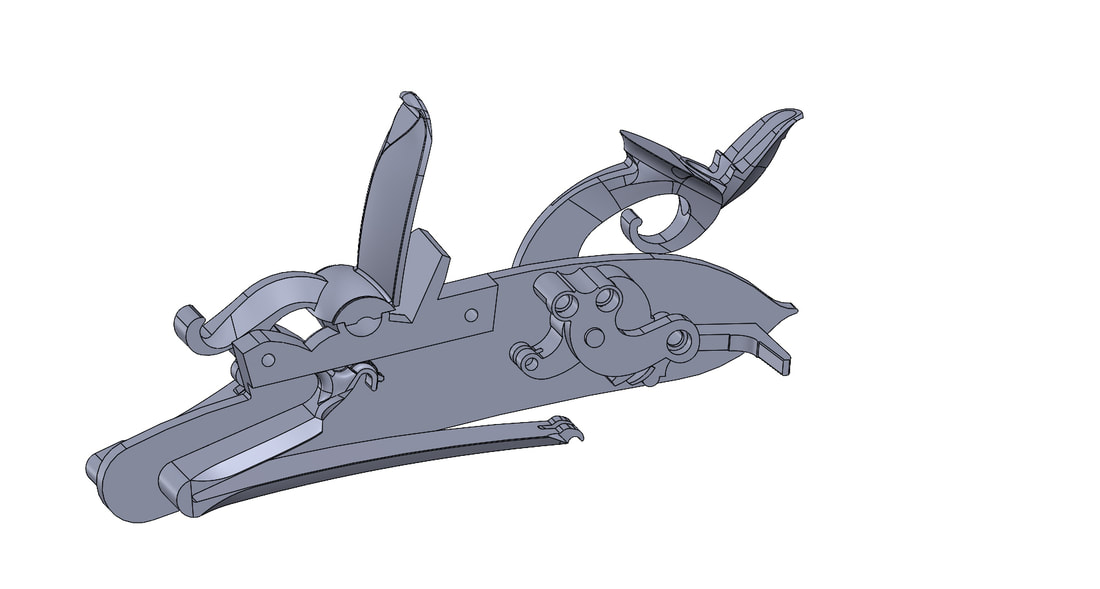

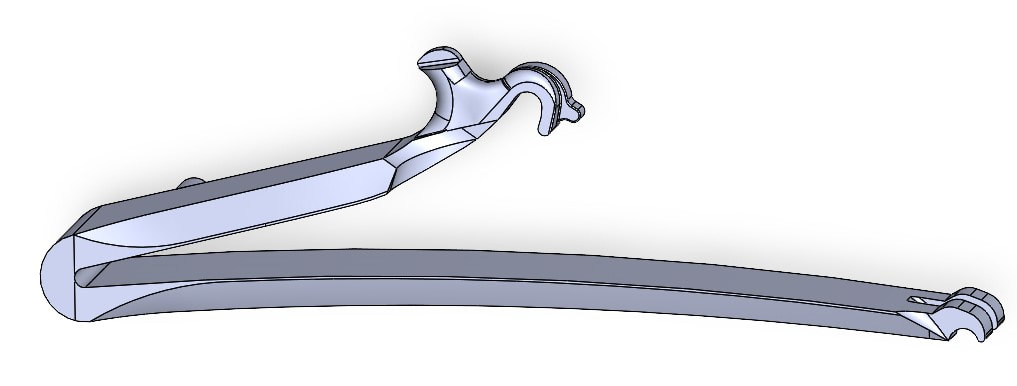

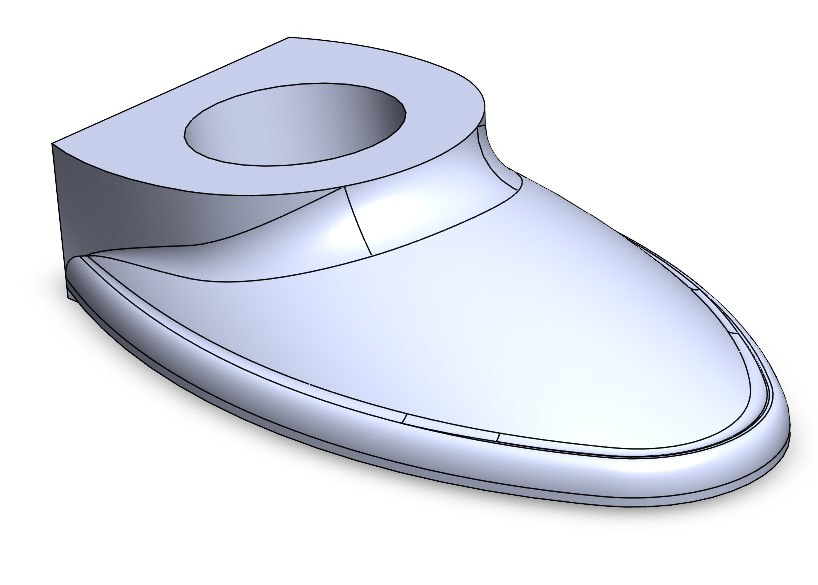

FrizzenThis part actually looks harder than it is. Most of it is symmetric. The most difficult feature was the small, turned up feature in the lower right.

Original Part

Model

Metal 3D Printed Part |

Plate

The plate holds it all together and everything aligns to this one part. It looks simple enough but hides many secretes.

Original Part

Model

Metal 3D Printed Part |

|

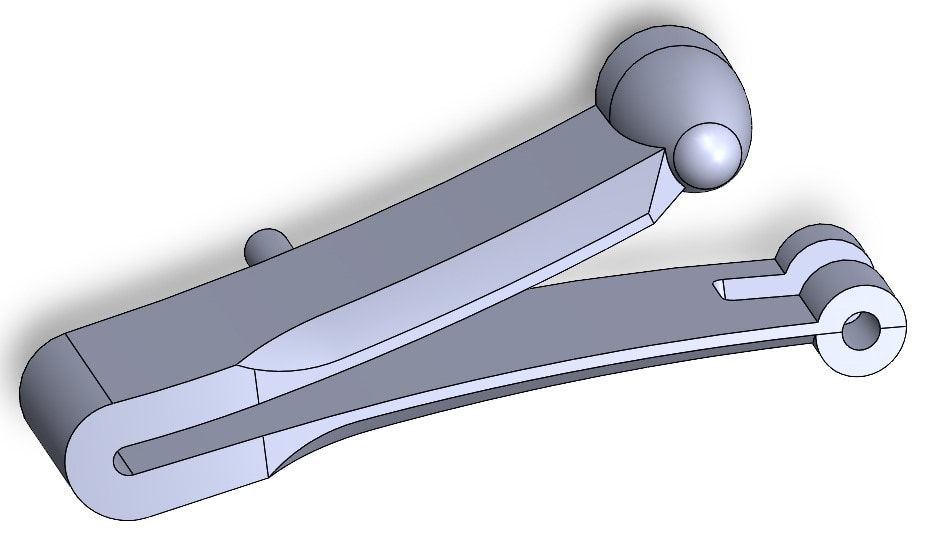

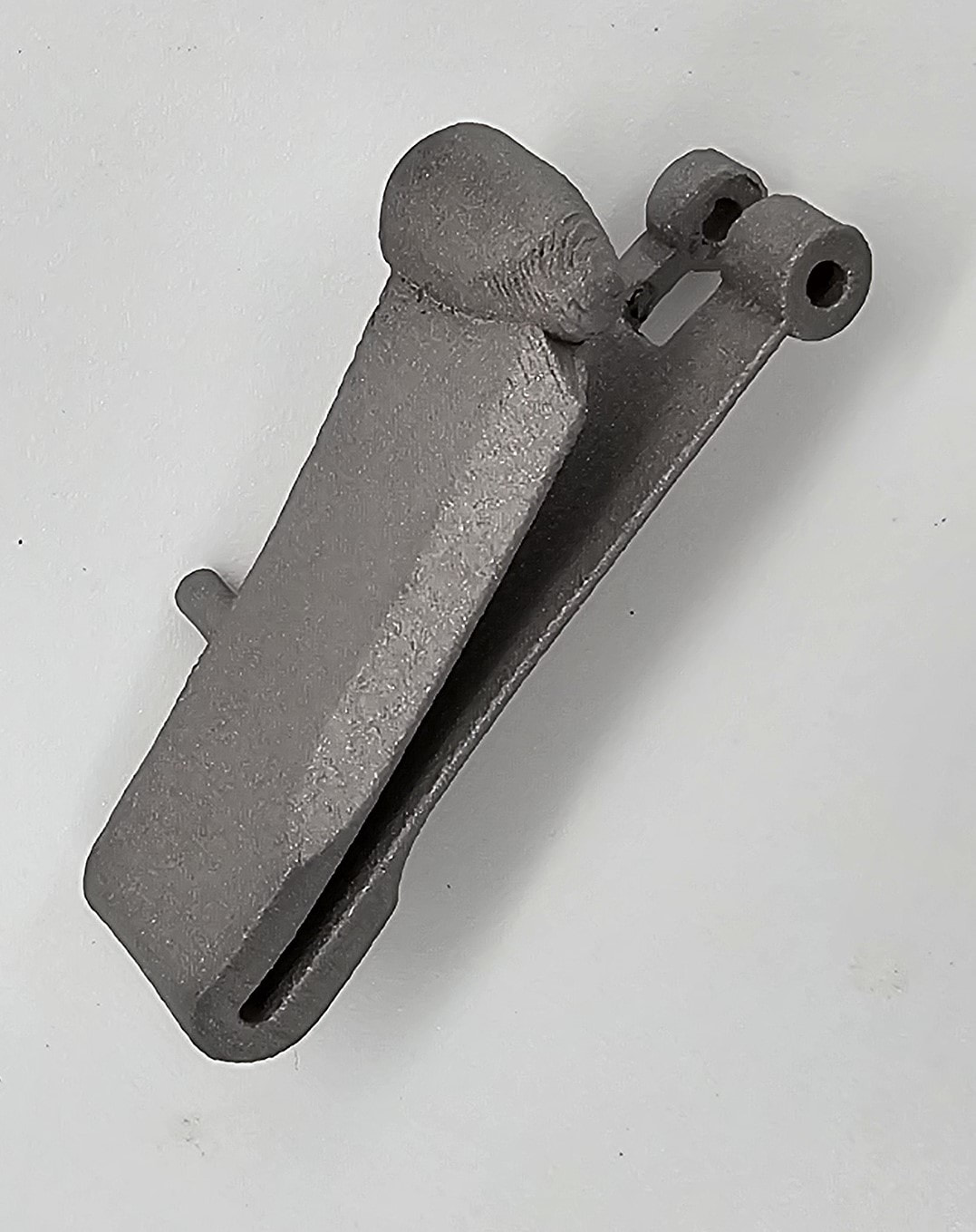

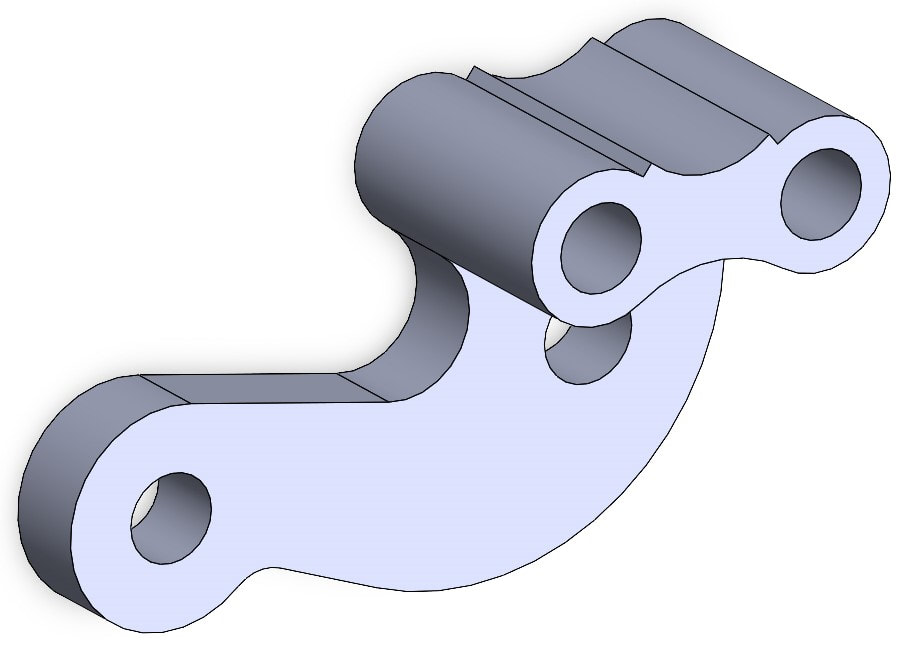

Sear

The sear is a critical part that teeters on the edge of dainty but this coupled with the tumbler are perhaps the most critical for safety and consistency to the whole system.

Original Part

Model

Metal 3D Printed Part

|

|

|

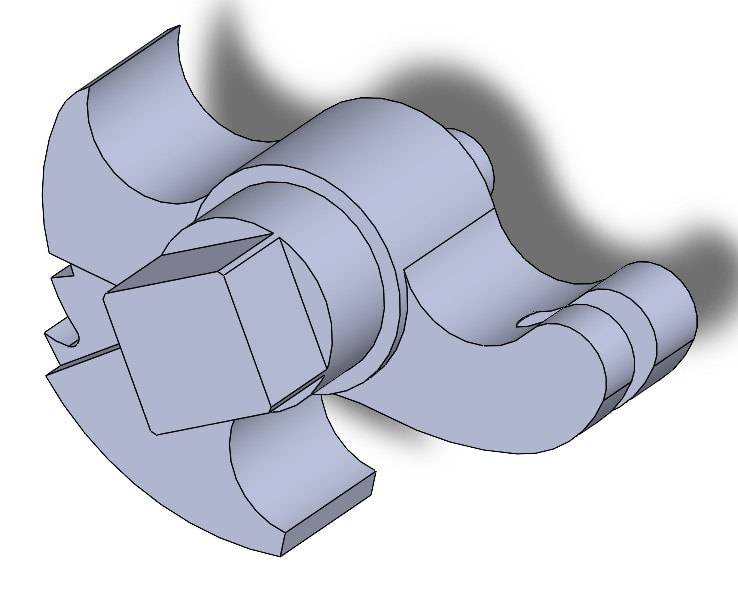

Tumbler

This is perhaps my favorite part of them all. The tumbler is the heart of the system and truly a thing of wonder. Clearance and high resolution features along with tempering always amaze.

Original Part

Model

Metal 3D Printed Part

|

|

Current Project Status:

The 3D printed parts were used to generate tooling for casting. One of the parts (not telling) must be machined for specific material properties relative to function.

The stocks are new and custom to the new product launch. These will be made in house at BuckRidge Flintlock.

I'm genuinely excited to the launch of this new product and I'll be one of the first in line to purchase one.

Again, check out BuckRidge Flintlocks at https://www.buckridgeflintlocks.com/ and tell them I sent you.

Stay tuned for more images, updates and other amazing projects.

The stocks are new and custom to the new product launch. These will be made in house at BuckRidge Flintlock.

I'm genuinely excited to the launch of this new product and I'll be one of the first in line to purchase one.

Again, check out BuckRidge Flintlocks at https://www.buckridgeflintlocks.com/ and tell them I sent you.

Stay tuned for more images, updates and other amazing projects.